Verco's GHG models have been used to footprint a third of the world's beer

For over a decade, Verco has partnered with some of the world's largest brewing companies, helping them develop actionable energy efficiency and decarbonisation plans. Our unique combination of expertise in brewing processes, energy and water efficiency and decarbonisation technologies sets us apart.

Our GHG models have been used to footprint breweries responsible for a third of the world’s beer. In the past 2 years, we have conducted detailed assessments in more than 11 countries across 5 continents, covering breweries with a combined consumption of more than 1,800 GWh. On average, we have identified energy reduction opportunities of 35%.

How does Verco work with breweries?

Here are a few examples of how we’ve helped various breweries work towards their decarbonisation goals:

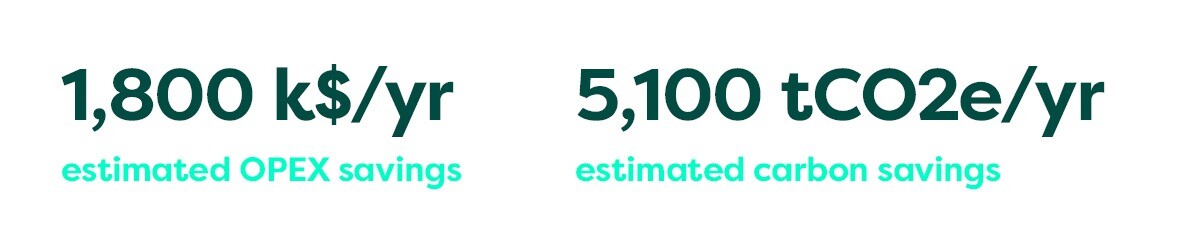

Brewery 1 – South America

“Supporting such a large brewery (producing over billions of pints per year!) that has a diverse product range and extensive packaging capabilities was an exciting challenge. Our team spent eight days on site to understand the intricacies of site operations, gather key data and quantify opportunities. Our approach was to spend as much time as possible with site teams to understand in detail how site processes worked, then challenge the site using our industry-specific knowledge. We were also able to identify reduction opportunities during the visit that were immediately acted upon, proving reductions can be made with relatively little resource effort.”

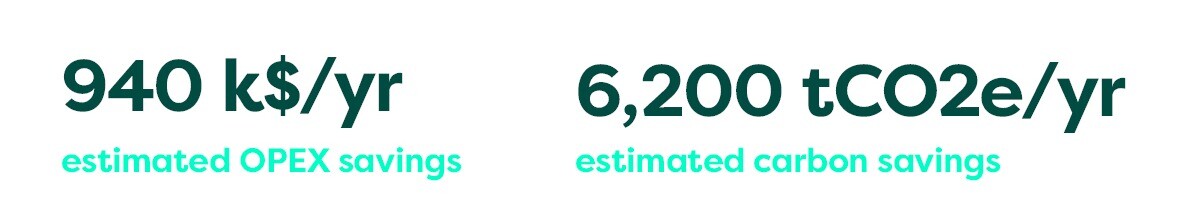

Brewery 2 – North America

“For a week, we worked closely with the site team, drawing on our expertise in brewing and energy reduction to identify efficiency improvements across the operation. By understanding the specific processes and challenges they faced onsite, we were able to prioritise the most impactful opportunities for energy reduction. Six months on, we continue to have regular check-ins with the site team. It's been great to see many of the identified opportunities implemented – resulting in a clear reduction in their overall energy demand!”

Brewery 3 – Central America

“Supporting one of the world's biggest breweries was a daunting challenge given the sheer size of the site's footprint, as well as language differences and operational setup. Our team of three visited the site for two weeks and were able to comprehensively understand the interplay of the site's thermal supply and demand system, then quantify major opportunities. Since their implementation we have seen a major reduction in utility demand.”

Verco Director of Corporates, Andrew Todd, said: “We’ve been working closely with breweries for over 15 years now, refining our knowledge of the sector and processes. At this stage, we consider brewery decarbonisation one of our specialisms. We recently helped one large brewery achieve a 20% improvement in energy efficiency within six months of our study. Another major brewery saw a 7.5% improvement just two months after our support. We’re proud of these successes and look forward to applying our knowledge to more carbon reduction journeys in the future.”

To find out more about our deep-dive audits for breweries, visit our case studies page. If you're interested in a deep-dive audit, get in touch.

And next time you settle down with a cold beer, think of us!