Is your industrial Energy Management System fit for zero?

A quick, simple guide for group and site managers on BEMS and M&T systems.

Effective energy management and improvement requires access to good quality data. Many businesses in industry are not clear when deciding which system to use to effectively manage, track, report and improve utility consumption and cost. Also, often group and site managers inherit legacy systems at varying maturity levels and state of operation. In this article we explain the main attributes, uses and applicability of Building Energy Management Systems (BMS) and Monitoring and Targeting systems (M&T).

BEMS

BEMS are designed to monitor and control building services to ensure optimal level of efficiency is achieved. Services include lighting, air-conditioning and heating among others. The system monitors operating and external parameters e.g. occupancy, temperature and adjusts the operation of services to ensure minimal energy wastage against pre-determined parameters. They can be stand-alone but are often integrated with other systems such as fire detection and CCTV to form a more complete building management system (BMS).

M&T system

M&T systems are designed to collect and analyse energy use, compare it against historical and benchmark consumption and enable improvement by setting targets. Reporting and taking action are integral parts of a monitoring and targeting system. Depending on the system in place, additional functionalities such as predicting, actively tracking energy consumption, exception alerting and automatic opportunity identification make M&T a powerful ally in reducing utility consumption and cost.

How do they compare?

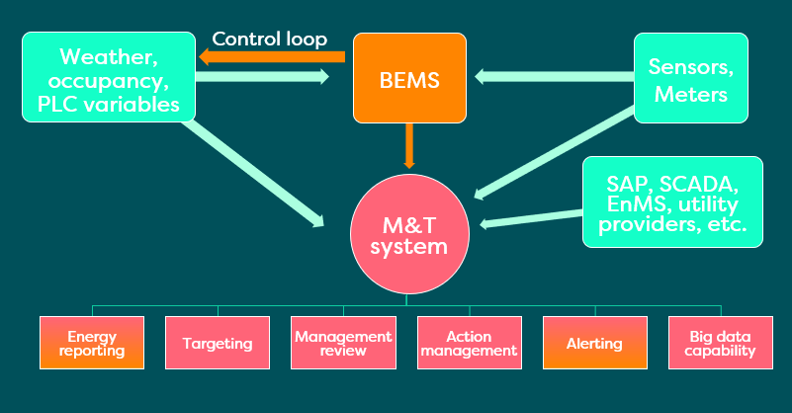

It should be apparent by now that a BEMS and an M&T system are not performing all the same functions and are not mutually exclusive; integration is possible as part of a wider infrastructure system and an example can be seen in the following diagram. Choosing one and/or the other depends on business and site requirements.

BEMS control equipment to ensure that operation does not deviate from design; this is dependent on what the design principles are and those may need to change over time. Given the right setup and frequent review, BEMS systems can avoid overconsumption and energy waste over time. BEMS are not suited to industrial processes due to their limited functionality and the relative complexity of industrial processes which are often controlled by other systems (e.g. SCADA/PLC). However, smart integration with advanced sensor technology may have additional benefits in staff comfort and working conditions.

BEMS systems generally take data from set sources and are less flexible on collecting other useful data; they are often locally installed and/or have restrictive licenses that restrict their use to a small number of operational users onsite.

On the other hand, M&T systems have no control functionality. They can integrate data from multiple sources and allow complex analysis over extended time periods. Regular use of a M&T system can result in significant long-term energy and cost savings year after year. The M&T interface and functionality makes it generally more suitable for ongoing energy management and tracking of opportunities, quantifying loss or improvement and corrective action tracking.

The best M&T platforms will be flexible enough to pull data from a BEMS to allow the data to link into the management level review but still maintain the use of the BEMS as originally intended. M&T systems generally provide a much broader level of access.

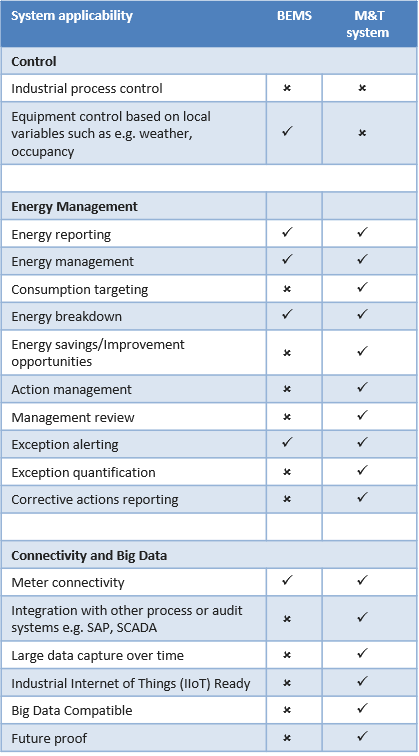

A summary assessment of system applicability is presented below to provide guidance to site and group managers. Please note the list is not exhaustive but provides directions to the most frequently asked questions.

What next for BEMS and M&T platforms?

BEMS have certainly found a place in the “Smart Buildings” revolution and can potentially be part of an effective energy management system in industry. BEMS tend to be limited local offline systems, so future proofing normally means physical hardware upgrades on site. On the other hand M&T platforms are not limited by local hardware and as part of the cloud are updated and developed regularly. As the Industrial Internet of Things (IIoT) takes off, there is a risk that physical hardware becomes obsolete very quickly, so any system that site managers choose should be scalable and capable of being regularly updated, preferably remotely; otherwise, there is a risk that the system becomes obsolete very quickly and becomes a commodity with limited functionality.

In a following article, we will look at how industrial data can be integrated using technology, software and innovation.

Contact us about getting the best out of your data